MENUMENU

- Home

- Corporate

- Services

- Manufacture

Fume Hoods

Accessories

- Laboratory Equipment

- Contact

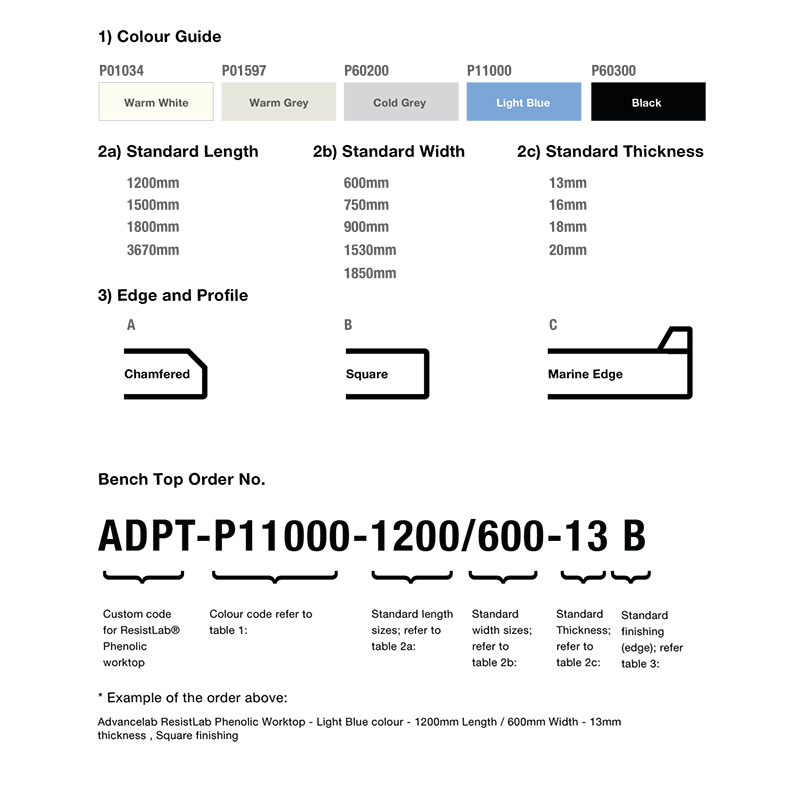

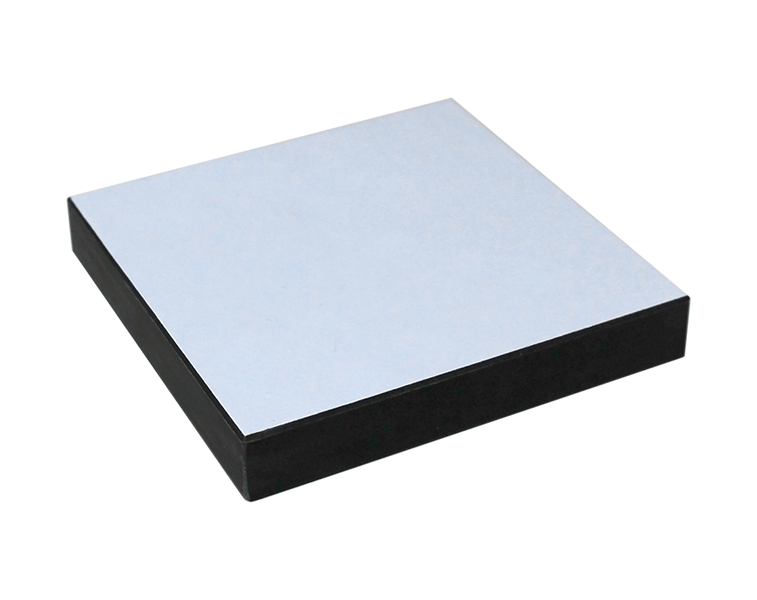

A regional builder & manufacturer specilizing in factory fit outs. ISO 9001 and ISO 18001 facilities. Phenolic worktops are the most commonly used tabletops in laboratories world wide. Up to 95% of all labs were phenolic tops. It has chemical resistance, high heat tolerance and is a robust material that is economical.

We have ResistLab® that we regularly use for all segments of industries included

Our work surfaces are molded with five thickness options:

You can view more information here. View Detail

Number |

Test Method |

Property / Attribute |

Unit (min. or max.) |

Values |

|

Resistance to Surface Wear |

10 |

Wear Resistance |

Revolutions (min.) Initial point Wear value |

150 350 |

|

Resistance to Impact by Large Diameter Ball |

21 |

Drop Height a) |

mm (min.) (t=nominal thickness) 2.0 ≤ t < 6.0 6.0 ≤ t |

1400 1800 |

|

Resistance to Scratching |

25 |

Force |

Rating (min.) Textured finishes |

3 |

|

Resistance to Dry Heat (180º C) |

16 |

Appearance |

Rating (min.) Textured finishes |

4 |

|

Resistance to Wet Heat (100º C) |

EN12721 |

Appearance |

Rating (min.) Textured finishes |

4 |

|

Resistance to Immersion in Boiling Water |

12 |

Mass Increase Thickness Increase Appearance |

5 (max.) 2.0 mm ≤ t < 5.0 mm t ≥ 5.0mm % (max.) (t=nominal thickness) 2.0 mm ≤ t < 5.0 mm t ≥ 5.0mm Rating (min.) Textured finished |

5.0, 2.0 6.0, 2.0 4 |

|

Dimensional Stability at Elevated Temperature |

17 |

Cumulative Dimentional Change |

% (max.) (t=nominal thickness) 2.0 mm ≤ t < 5.0 mm L 2.0 mm ≤ t < 5.0 mm T t ≥ 5.0 mm L t ≥ 5.0 mm T |

0.40 |

| Resistance Staining | 26 |

Appearance |

Rating (min.) Groups 1&2 Group 3 |

5 |

| Lightfastness (Xenon Arc) | 27 |

Contrast |

Grey scale rating |

4 to 5 |

| Resistance to Water Vapour | 14 |

Appearance |

Rating (min.) Textured finishes |

4 |

| Resistance to Cigarette Burns | 30 |

Appearance |

Rating (min.) |

3 |

| Resistance to Crazing | 24 |

Appearance |

Grade (min.) |

4 |

| Flexural Modulus | EN ISO 178 d) |

Stress |

Mpa (min.) |

9000 |

| Flexural Strength | EN ISO 178 d) |

Stress |

Mpa (min.) |

80 |

| Tensile Strength | EN ISO 527 d) |

Stress |

Mpa (min.) |

60 |

| Density | EN ISO 1183 |

Density |

kg/m³ (min.) |

1350 |