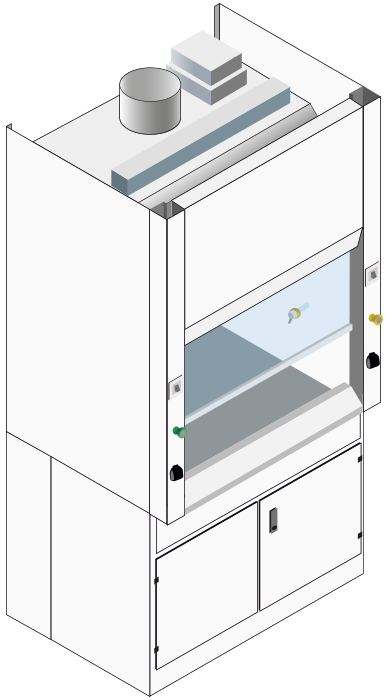

Laboratory fume hoods or fume cupboards represent the primary line of defense for personnel against exposure to harmful, toxic and dangerous fumes or chemicals as they are produced.

“Fume hoods are essentially aerodynamic scavenging devices that remove dangerous fumes from a laboratory and expel it into the environment where it is sufficiently diluted to no longer pose a health risk.”

Advancelab Laboratory fume hoods have been manufactured to provide the highest levels of safety for laboratory personnel. Fume hoods when sized with an appropriate chemical resistant centrifugal exhaust fan will protect laboratory staff from exposure to harmful fumes. Please contact our distributors or offices to help or design an efficient exhaust system.